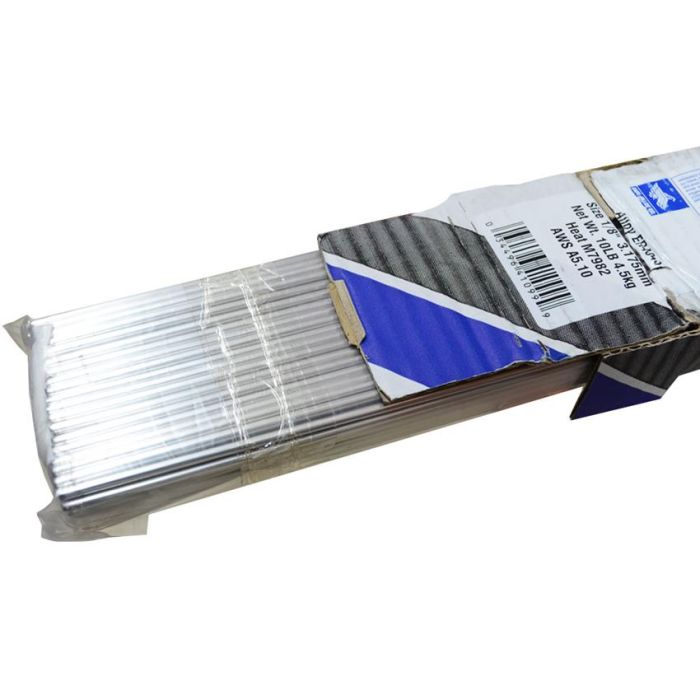

ROD TIG 1/8"4043 ALUM 5KG

WASHINGTON ALLOYS

2.4mm 4043 Aluminum Tig Welding Rod

PRODUCT DESCRIPTION

Aluminum MIG welding wire /aluminum alloy welding wire ER4043 is a kind of aluminum & silicon alloy welding wires with 5% silicon; also name S331; and this product is of good liquidity; good forgeability; but lack of ductility. Due to the high silicon content; when used in the welding of high magnesium alloy; easily generated in the weld brittle Mg2Si; reduce the plasticity and the corrosion resistance of joint. In addition; the welding surface color dark; anodized after more different with parent metal color.

TECHNICAL SPECIFICATIONS

Chemical parameters (by weight %):

Si 4.5-6

Fe 0.80

Cu 0.30

Mn 0.05

Mg 0.05

Cr ---

Zn 0.10

Ti 0.2

Be 0.03

Al Other

Characteristics:

Melting range 1065 - 1170°F

Electrical conductivity 42%IACS(O)

Density 2.68g/mm3

Anti corrosion performance B(Gen) A(SCC)

The coefficient of thermal expansion (20 ? -300 ?) 22×10-6/K

Thermal conductivity (20 ?) 170W/m·K

Application:

ER4043 is for welding heat-treatable base alloys and more specifically 6xxx series alloy. It can also be used for jointing wrought to cast materials.

ER4043 can be used to weld various grades of aluminum base metals like automotive components such as frame and drive shafts; bicycle frames; ship; chemistry equipment; mould furnitures;vessel; containers; etc.

Advantages:

1.Little Spatter

2. Excellent welding process

3. Very good for machinable

4.Pure nickel core

5. Both AC and DC applicable

6. Weldment: no need to preheat; good crack resistibility and process-ability

WEIGHT 1LB"

WASHINGTON ALLOYS

2.4mm 4043 Aluminum Tig Welding Rod

PRODUCT DESCRIPTION

Aluminum MIG welding wire /aluminum alloy welding wire ER4043 is a kind of aluminum & silicon alloy welding wires with 5% silicon; also name S331; and this product is of good liquidity; good forgeability; but lack of ductility. Due to the high silicon content; when used in the welding of high magnesium alloy; easily generated in the weld brittle Mg2Si; reduce the plasticity and the corrosion resistance of joint. In addition; the welding surface color dark; anodized after more different with parent metal color.

TECHNICAL SPECIFICATIONS

Chemical parameters (by weight %):

Si 4.5-6

Fe 0.80

Cu 0.30

Mn 0.05

Mg 0.05

Cr ---

Zn 0.10

Ti 0.2

Be 0.03

Al Other

Characteristics:

Melting range 1065 - 1170°F

Electrical conductivity 42%IACS(O)

Density 2.68g/mm3

Anti corrosion performance B(Gen) A(SCC)

The coefficient of thermal expansion (20 ? -300 ?) 22×10-6/K

Thermal conductivity (20 ?) 170W/m·K

Application:

ER4043 is for welding heat-treatable base alloys and more specifically 6xxx series alloy. It can also be used for jointing wrought to cast materials.

ER4043 can be used to weld various grades of aluminum base metals like automotive components such as frame and drive shafts; bicycle frames; ship; chemistry equipment; mould furnitures;vessel; containers; etc.

Advantages:

1.Little Spatter

2. Excellent welding process

3. Very good for machinable

4.Pure nickel core

5. Both AC and DC applicable

6. Weldment: no need to preheat; good crack resistibility and process-ability

WEIGHT 1LB"

| SKU | WASH-ER40431836 |

|---|---|

| Weight | 1.000000 |

| Manufacturer | WASHINGTON ALLOY |

Payment Plan:

The items you need are well within your reach. ShopSSLTT has the premium products you want at affordable prices and with our shop now pay later payment plans we make them accessible to all. Lear more on the following links

Payment plan Details : You can now finance your purchases with flexible payment planss clich here to learn how.

Requirements: Before you apply for the plan make sure you have all the required documents, click here to see the list of documents required.