Flame Industries Limited visit to DuPont Innovation Centre, Sao Paulo Brazil, June 2016

Flame Industries Limited, in their ongoing campaign to educate end-users about the unique features of Nomex from Du Pont Technologies Limited, accepted an invitation from DuPont Technologies Limited, for their Management team along with some of their customers to visit the DuPont Innovation Centre in Sao Paulo Brazil for one week in June.

This visit allowed both Flame Industries Limited and its customers to receive firsthand knowledge and insight into the operations of the Innovation Centre.

The group was allowed access to research and testing the lab at the inovation centre, where a multitude of tests were conducted on the various fabrics as follows;

The Chlorine Test:

Two beakers were filled with bleach, two samples of “F.R.” (Fire Resistant) cloth was dipped in the beakers. One of the samples was DuPont Nomex Comfort, while the other was treated cotton fabric. It was clear to see that allot of reaction took place with the beaker that contained the Bleach and treated fabric, with the presence of bubbles. The container containing Bleach and the Nomex fabric sample had no reaction, signified by the absence of any bubbles.

The presence of the bubbles in the container containing the treated fabric signifies a reaction-taking place and its means that the “FR” treatment contained in the fabric was being removed or washed out. Hence this would it would loose its “FR” properties after a few washes.

The absence of the bubbles in the container containing the Nomex fabric signifies that no reaction took place. This means that the Nomex fabric would retain its “FR” properties even if bleach were to be added when laundering garments.

Washing “FR” garments with bleach is still not recommended, although in the case of Nomex the fabric retains it “FR” prosperities, the bleach would affect the colour and the “Wear and Tear” on the fabric.

Tear Strength Test and Cut Strength Test

The machinery used to measure the tear strength of the various fabrics was shown along with another machine used to test the cutting limitations of the fabrics. These machines are used to determine the wear and tear of different fabrics.

Fabric Analyzer

The equipment used to determine the unique “finger print" or "signature” of different fabrics was also used and the group experienced a practical test using the machine. Each fabric has a different digital “Finger print or Signature” and it can be shown graphically. Samples brought were tested and compared to different fabric signatures. There were samples brought by customers, which contained a different fabric “fingerprint” than the fabric the material was supposed to be made off. The presenter mentioned that this machine along with other test help determine which fabric garments are made from.

Vertical flame test

The vertical flame test was also performed and once again customers got a first hand comparison of the performance of Nomex compared to “FR” cotton. The Nomex fabric passed the test performed according to the standards, while the other fabric did not meet the requirements according to the standards.

DuPont Thermo Man

The highlight of the workshop was meeting the much anticipated “DuPont Thermo Man”

Thermo Man is a mannequin used by DuPont and regulatory bodies to test the fire resistant properties of constructed garments. The technology was developed by Du Pont and is currently used as the governing standard to determine and test the “FR” properties of fabrics.

The Thermo Man is outfitted with heat sensors at strategic points to simulate the way heat is applied to the human body in the event of a fire. The mannequin is placed in a controlled enclosure where jets apply fire to the mannequin for a specific amount of time to simulate an industry fire and escape time.

Flame Industries Limited brought a sample of their garment and it was placed on the mannequin. The test was done and the garment returned a result of 24% burn injury.

Customers also brought their products made by local manufacturers in Trinidad and Tobago.

DuPont also provided samples of Nomex comfort and treated cotton on thermo man and results were compared. In all cases the garments made of Nomex had better results than other “FR” fabrics.

Flame Industries Limited, in its continued effort of making the workplace and its employees safe was very proud to be part of this eye-opening Thermoman Workshop, hosted by DuPont Technologies Limited. We would like to thank DuPont for extending this invitation to our management and valued customers.

To our valued customers, we also thank you for making the time to attend this workshop, it was greatly appreciated.

When it comes to safety wear, the power is in your hands, so please make the right decision and protect yourself with the best! You can visit and like our facebook page to see the full album and subscribe to our mailing list to be the first to know about our group's promotions, events and activities.

SSL Featured Deals

Great Deals Available

-

ROUTER PLUNGE & FIXED BASE 1/4"&1/2"COLLET 14AMP 2.5HP VSPD LCD DISPLAYTTD $ TTD $1,199.00

ROUTER PLUNGE & FIXED BASE 1/4"&1/2"COLLET 14AMP 2.5HP VSPD LCD DISPLAYTTD $ TTD $1,199.00 -

DRILL ROTARY HAMMER SDSMAX 2"14#15A, 19J 1510W 310RPM 2250BPM VSPTTD $ TTD $8,399.95

DRILL ROTARY HAMMER SDSMAX 2"14#15A, 19J 1510W 310RPM 2250BPM VSPTTD $ TTD $8,399.95 -

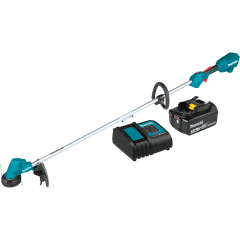

BRUSHCUTTER 17"BL 36V 2X6.0AH UHANDLE EQUIVALENT TO 30CC 1.3HP ENGINETTD $ TTD $4,129.00

BRUSHCUTTER 17"BL 36V 2X6.0AH UHANDLE EQUIVALENT TO 30CC 1.3HP ENGINETTD $ TTD $4,129.00